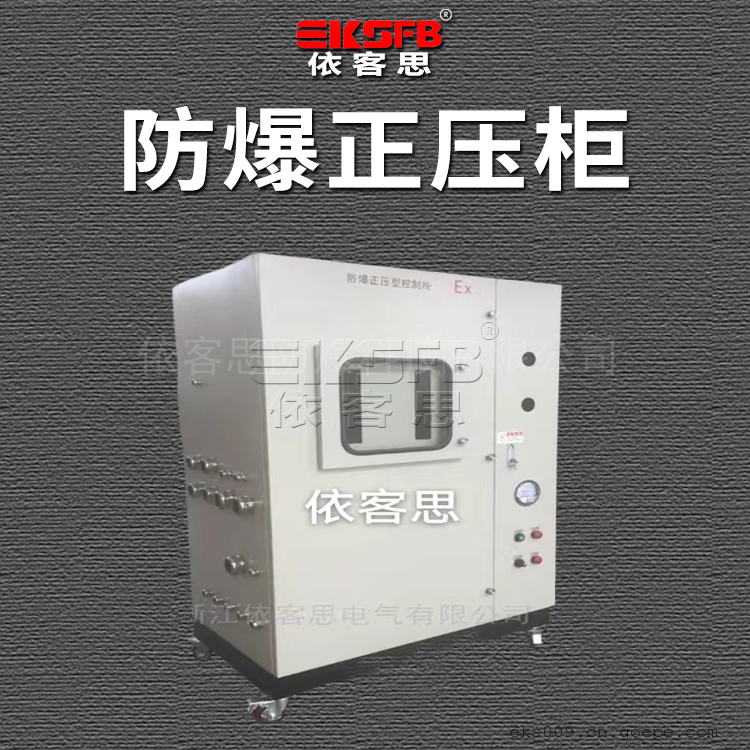

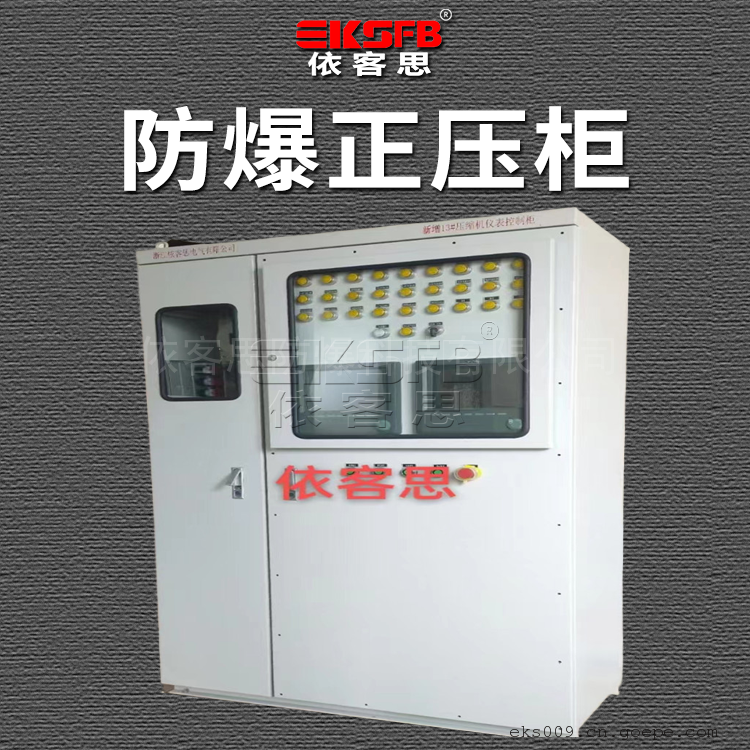

依客思防爆站房司钻房防爆小屋正压防爆房资质齐全PXK-T 

详细信息

| | 品牌:依客思 | | 型号:PXK-T | | 加工定制:是 | |

| | 是否进口:否 | | 规格:PXK-T | | 用途:正压柜是向柜内输入气体,使柜内的压力高于外部的压力,形成一 | |

PXK防爆正压柜是向柜内输入气体,使柜内的压力高于外部的压力,形成一个安全正压环境。从而阻止可燃性气体或可燃性粉尘进入柜体,使柜内的普通元器件得到正常的运行。正压柜有两种材质,一种是Q235钢板焊接材质,一种是304不锈钢材质。而正压柜有三种结构:分别是单腔式的左右结构,上下式结构、琴台式结构。它的使用场所也很广泛,适用于石油化工、海上钻井平台、冶金、医药、轻工、纺织、酿酒、油漆、涂料、食品、生物工程、航天航空工程以及军事设施等工厂中。

PXK防爆正压柜---------适用范围

1.适用于爆炸性气体环境1区、2区危险场所;

2.适用于IIA、IIB、IIC级爆炸性气体环境;

3.适用于可燃性粉尘环境20区、21区、22区;

4.适用于温度组别为T1—T6的环境;

5.本产品适用于石油化工、海上钻井平台、冶金、医药、轻工、纺织、酿酒、油漆、涂料、食品、生物工程、航天航空工程以及军事设施等工厂中;

防爆正压柜---------执行标准:

GB3836.1、GB3836.2、GB3836.3、GB12476.1、

1、控制电源:220V 380V AC。

2、运行正压值150Pa-900Pa

>900Pa自动排气

<150Pa自动补气

3、临界正压值:>1000Pa手动排气 <70pa自动切断电源

4、气源:不低于0.4Mpa的洁净空气和保护气体

5、防爆标志: Ex de ib mb pz IICT4 Gc

6、外壳防护等级:不低于IP54

PXK防爆正压柜功能特色

◆为专用于2区而设计的一种正压防爆柜,pz系列防爆正压柜标志换气时间和流量,安装了节流阀和安全阀等安全装置,采用纯气动控制方式,无需电源,用户按提示进行相应的调试、运行。

◆pz型正压柜适用于2区爆炸性气体环境或22区可燃性粉尘环境;

◆产品无主、副盘,采用气动元件控制,控制部分包括减压阀、气源压力表、正压腔压力表换向阀和排气阀等;

通过精确计算设计相应控制气路大小规格,正压控制准确、可靠,是我公司开发的新一代正压防爆产品;

用户根据提示进行换气操作,换气完成后可向柜内供电。正常工作时压力在200Pa~600Pa之间,当压力高于1000Pa时,安全阀自动打开排气,自动调整内部气压,保证产品不受高气压冲击变形损坏,当压力低于100Pa时,气动指示灯报警,当气源故障,柜内压力长

期过低时,应切断前级电源:

◆正压控制部分不间断连续监控,并显示正压腔内压力参数;

◆不间断连续供风,正压腔内电器元件的工作热量可随时带走,具有良好的散热功能。内部可装检测仪表、分析仪表、显示仪表、低压电器、变频器、软起动器、计算机等,整台设备可作为设备起动、控制、中央信号处理及控制系统:

◆同型号产品可多台并联运行:

用户提供气源时,须配备洁净空气或惰性气体气源,一般情况下,现场的仪表气源可满足要求,气源压力0.2MPa-0.8MPa:

外壳材质可选用不锈钢板焊接的产品,具有很好的防腐性能,可应用于强腐蚀要求的石油、化工、轮船等场所。

PXK explosion-proof positive pressure cabinet is to input gas into the cabinet, so that the pressure inside the cabinet is higher than the external pressure, forming a safe positive pressure environment. Thus, combustible gas or combustible dust is prevented from entering the cabinet, so that the ordinary components in the cabinet can operate normally. Positive pressure cabinet has two kinds of materials, one is Q235 steel plate welding material, the other is 304 stainless steel material. The positive pressure cabinet has three kinds of structures: single cavity left and right structure, up and down structure, piano table structure. It is also widely used in petrochemical, offshore drilling platforms, metallurgy, medicine, light industry, textile, wine, paint, coatings, food, biological engineering, aerospace engineering and military facilities and other factories.

PXK explosion-proof positive pressure cabinet --------- Scope of application

1. Suitable for explosive gas environment zone 1, zone 2 dangerous places;

2. Suitable for IIA, IIB, IIC explosive gas environment;

3. Applicable to combustible dust environment 20 zone, 21 zone, 22 zone;

4. Suitable for temperature group T1-T6 environment;

5. This product is suitable for petrochemical, offshore drilling platform, metallurgy, medicine, light industry, textile, wine, paint, coatings, food, biological engineering, aerospace engineering and military facilities and other factories;

Explosion-proof positive pressure cabinet --------- Implementation standard:

GB3836.1, GB3836.2, GB3836.3, GB12476.1,

1. Control power supply: 220V 380V AC.

2, running positive pressure value 150Pa-900Pa

> 900Pa automatic exhaust

< 150Pa automatic air replenishment

3, the critical positive pressure value: > 1000Pa manual exhaust < 70pa automatically cut off the power supply

4, air source: not less than 0.4Mpa of clean air and protective gas

5, explosion-proof mark: Ex de ib mb pz IICT4 Gc

6, shell protection level: not less than IP54

PXK explosion-proof positive pressure cabinet features

◆ A positive pressure explosion-proof cabinet specially designed for the 2 zone, pz series explosion-proof positive pressure cabinet marks the air exchange time and flow, and is installed with throttle valve and safety valve and other safety devices, using pure pneumatic control mode, no power supply, the user carries out the corresponding debugging and operation according to the prompt.

◆pz type positive pressure cabinet is suitable for explosive gas environment in zone 2 or combustible dust environment in zone 22;

◆ The product has no main or auxiliary disc, and is controlled by pneumatic components. The control part includes pressure reducing valve, air source pressure gauge, positive pressure chamber pressure gauge reversing valve and exhaust valve, etc.

Through accurate calculation and design of corresponding control gas path size specifications, positive pressure control is accurate and reliable, is a new generation of positive pressure explosion-proof products developed by our company;

The user can carry out air exchange operation according to the prompt, and supply power to the cabinet after air exchange is completed. Normal working pressure between 200Pa~600Pa, when the pressure is higher than 1000Pa, the safety valve automatically opens the exhaust, automatically adjust the internal air pressure, to ensure that the product is not damaged by high pressure impact deformation, when the pressure is lower than 100Pa, the pneumatic indicator alarm, when the air source failure, the cabinet pressure is long

When the period is too low, the preceding power supply should be cut off:

◆ The positive pressure control part is continuously monitored and displays the pressure parameters in the positive pressure chamber;

◆ Uninterrupted continuous air supply, the working heat of the electrical components in the positive pressure chamber can be taken away at any time, with good heat dissipation function. Inside can be installed detection instrument, analysis instrument, display instrument, low voltage electrical appliances, frequency converter, soft starter, computer, etc. The whole equipment can be used as equipment starting, control, central signal processing and control system:

◆ Multiple parallel operation of the same model:

When the user provides the air source, it must be equipped with clean air or inert gas source. In general, the on-site instrument air source can meet the requirements, and the air source pressure is 0.2MPa-0.8MPa:

Shell material can be selected stainless steel plate welding products, with good anti-corrosion performance, can be used in strong corrosion requirements of petroleum, chemical, ships and other places.

依客思防爆科技有限公司15392918022内容声明:谷瀑为第三方平台及互联网信息服务提供者,谷瀑(含网站、客户端等)所展示的商品/服务的标题、价格、详情等信息内容系由店铺经营者发布,其真实性、准确性和合法性均由店铺经营者负责。谷瀑提醒您购买商品/服务前注意谨慎核实,如您对商品/服务的标题、价格、详情等任何信息有任何疑问的,请在购买前通过谷瀑与店铺经营者沟通确认;谷瀑上存在海量店铺,如您发现店铺内有任何违法/侵权信息,请在谷瀑首页底栏投诉通道进行投诉。依客思防爆科技有限公司 电话:15392918022 手机:15392918022 地址: 湖北省武汉市江夏区金龙大街联东U谷江夏智能制造产业园

依客思防爆科技有限公司15392918022内容声明:谷瀑为第三方平台及互联网信息服务提供者,谷瀑(含网站、客户端等)所展示的商品/服务的标题、价格、详情等信息内容系由店铺经营者发布,其真实性、准确性和合法性均由店铺经营者负责。谷瀑提醒您购买商品/服务前注意谨慎核实,如您对商品/服务的标题、价格、详情等任何信息有任何疑问的,请在购买前通过谷瀑与店铺经营者沟通确认;谷瀑上存在海量店铺,如您发现店铺内有任何违法/侵权信息,请在谷瀑首页底栏投诉通道进行投诉。依客思防爆科技有限公司 电话:15392918022 手机:15392918022 地址: 湖北省武汉市江夏区金龙大街联东U谷江夏智能制造产业园 扫一扫,手机浏览

扫一扫,手机浏览