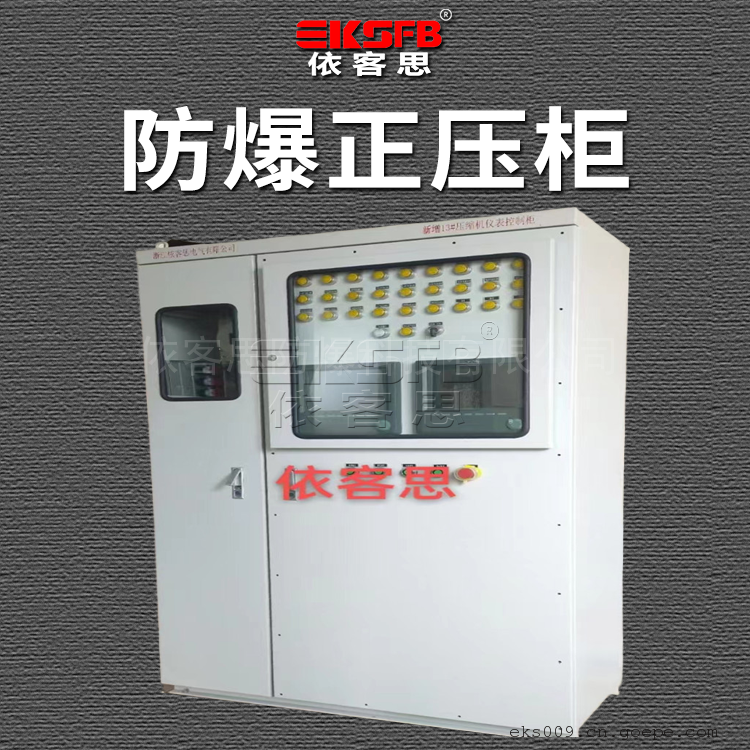

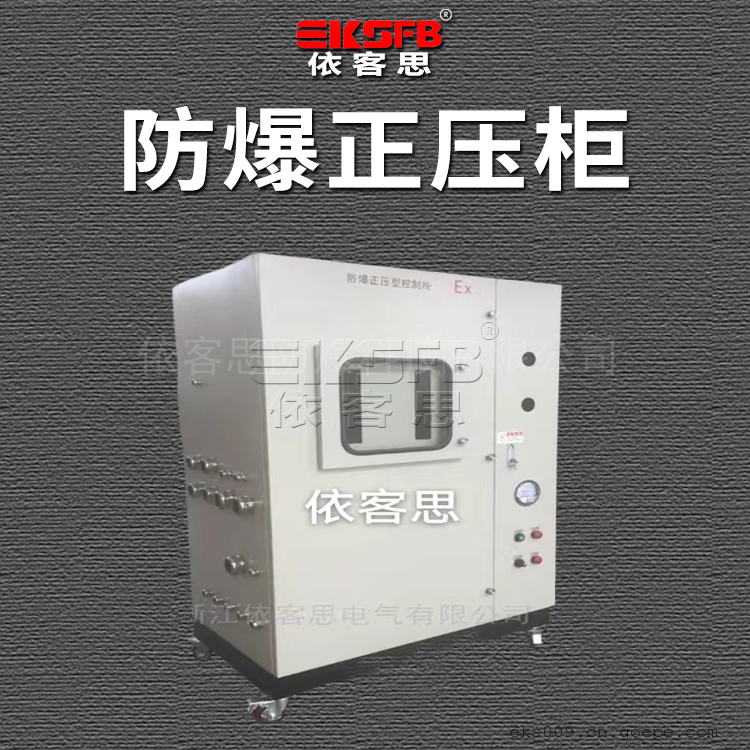

依客思PXK-TPXK系列钢板防爆正压柜-正压型防爆柜的特点

详细信息

| | 加工定制:是 | | 额定电流:100/80/63 A | | 短路关合电流:100 KA | |

| | 壳体防护等级:IP65 | | 外形尺寸:1500X1000X300 mm | | 外壳材质:钢板焊接/不锈钢 | |

| | 品牌:依客思 | | 型号:PXK-T | | | |

详细介绍:

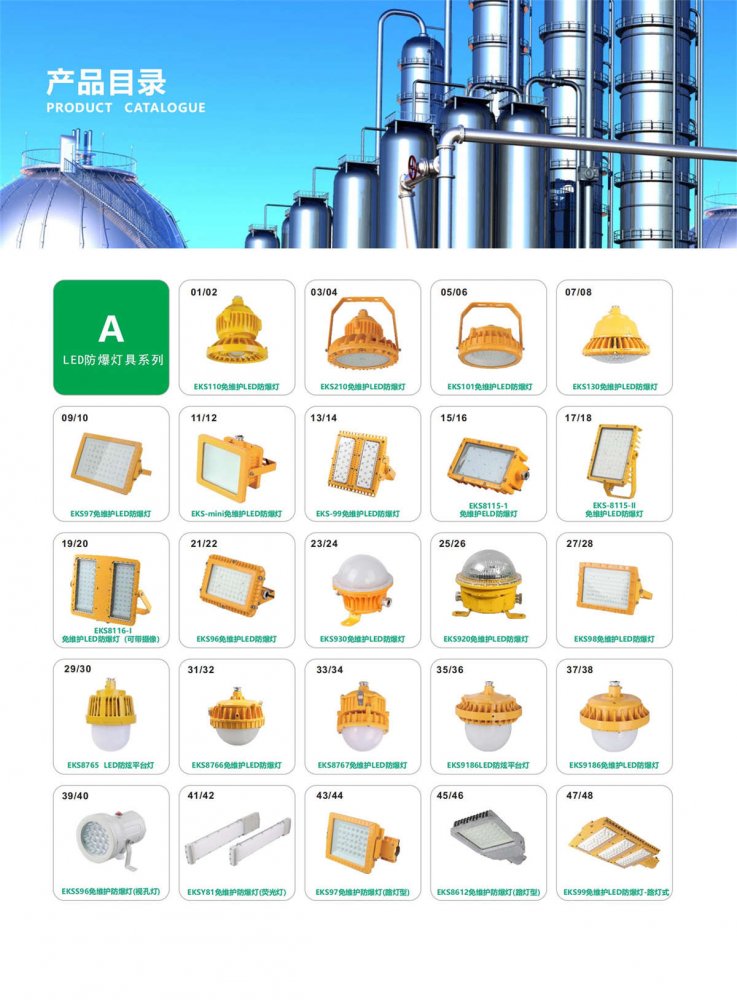

产品图片+产品样册+产品说明

正压防爆电气控制柜:安全与高效的保障

在石油化工、矿山、港口等易燃易爆环境中,正压防爆电气控制柜是必不可少的设备之一。它不仅能够有效地防止爆炸事故的发生,还能确保设备的正常运行,提高生产效率。

一、设计原理

正压防爆电气控制柜的设计原理主要是通过正压来防止爆炸性混合物的产生。在柜内,通过风机或者其他设备,始终保持一定的正压环境,使得爆炸性混合物无法进入柜内,从而避免了爆炸事故的发生。同时,柜内的电气设备也采用了防爆设计,使得设备能够在易燃易爆环境中安全运行。

二、制造工艺

正压防爆电气控制柜的制造工艺要求非常高。首先,材料的选择必须符合国家标准,具有良好的防爆性能和耐腐蚀性能。其次,制造过程中的焊接、装配、喷涂等工序都必须严格遵循工艺要求,确保设备的质量。*后,制造完成后,还需要进行严格的性能测试,包括防爆性能测试、耐腐蚀性能测试、抗干扰性能测试等,确保设备的性能指标符合国家标准。

三、使用与管理

正压防爆电气控制柜在使用过程中,必须严格按照操作规程进行,避免产生火花或者电弧,引起爆炸事故。同时,定期对设备进行检查和维护,确保设备的正常运行。在设备出现故障时,应及时进行处理,避免因设备故障而导致的安全隐患。

四:防爆正压柜的特点

A:防爆正压柜,正压型防爆柜,根据设计形式有:单腔式、上下式、左右式、琴台式。防爆正压柜,正压型防爆柜,根据材质有:Q235优质钢板、不锈钢钢可供客户选择。

B:不锈钢防爆正压柜的适用范围:

1. 适用于化工、海上钻井平台、冶金、医药、轻工、纺织、食品、生物工程、航天航空工程以及军工等bao zha性气体或粉尘环境中,作为三相四线制(380V/220V)交流低压电器配电系统供电或对检测仪表、分析仪表、jian shi器、微电脑触摸屏、大功率变频器等元件的监测和控制。

2.适用于1区、2区危险场所。

3.适用于IIA、IIB、IIC类,温度组别为T1-T4的bao zha性气体环境。

4.户内、户外安装。

C:不锈钢防爆正压柜的技术特点:

1.本产品主要由柜体、自控系统、布气系统、报警系统、配电系统组成;柜体由正压腔和副腔组成,正压腔内装用户的配电系统元件,副腔内装自控系统。

2.柜式产品采用GGD柜架,主副盘为左右结构,电缆沟座式安装,下进线、前门操作,后门检修。

3.箱式产品采用304不锈钢焊接结构,主、副盘为上下结构,挂式安装,下进线、前门操作和检修。

4.琴台式防爆正压柜产品为主、副盘为前后结构,座式安装,下进线、琴台操作,后门检修。

5.按进气方式分为通风型和补偿型。通风型为不间断连续供气,正压腔内装元件的工作热量可随气路带走,具有很好的散热功能,适用于解决大功率防爆变频器的散热问题;补偿型为间断性供气,正压腔要有良好的密封性,确保耗气量小。

6.用户须提供气源,要求为:净化空气或氮气,气源压为为:0.2~0.8Mpa;通常用户现场的仪表风均可满足要求。

7.不锈钢材质根据要求GB3280-84。

五:使用与管理

正压防爆电气控制柜在使用过程中,必须严格按照操作规程进行,避免产生火花或者电弧,引起爆炸事故。同时,定期对设备进行检查和维护,确保设备的正常运行。在设备出现故障时,应及时进行处理,避免因设备故障而导致的安全隐患。

总之,正压防爆电气控制柜是易燃易爆环境中不可或缺的设备之一。通过合理的设计、精湛的制造工艺和严格的使用管理,正压防爆电气控制柜能够有效地防止爆炸事故的发生,保障生产的安全和稳定,提高生产效率。

Positive Pressure Explosion-Proof Electrical Control Cabinet: Guarantee of Safety and Efficiency In flammable explosive environments such as petrochemicals, mines, and ports, the positive pressure explosion-proof electrical control cabinet is one of the indispensable devices. It can not effectively prevent explosion accidents but also ensure the normal operation of equipment, thereby improving production efficiency. I. Design Principle The design principle of the positive pressure explosion electrical control cabinet mainly involves preventing the formation of explosive mixtures through positive pressure. Inside the cabinet, a certain positive pressure environment is maintained through fans or other equipment preventing explosive mixtures from entering the cabinet and thus avoiding explosion accidents. Additionally, the electrical equipment inside the cabinet is designed with explosion-proof features, allowing the equipment operate safely in flammable and explosive environments. II. Manufacturing Process The manufacturing process of the positive pressure explosion-proof electrical control cabinet has very high requirements. Firstly the selection of materials must comply with national standards, possessing good explosion-proof and corrosion-resistant properties. Secondly, the manufacturing processes such as welding, assembly, and painting strictly follow the process requirements to ensure the quality of the equipment. Finally, after manufacturing is completed, strict performance testing is required, including explosion-proof performance testing corrosion resistance testing, and anti-interference performance testing, to ensure that the equipment's performance indicators meet national standards. III. Use and Management During the use the positive pressure explosion-proof electrical control cabinet, it is necessary to strictly follow the operating procedures to avoid the generation of sparks or arcs, which could cause explosion accidents Regular inspections and maintenance of the equipment are also required to ensure its normal operation. In case of equipment failure, timely handling is necessary to avoid potential safety hazards due equipment failure. IV. Features of the Explosion-Proof Positive Pressure Cabinet A: The explosion-proof positive pressure cabinet, positive pressure type explosion-proof cabinet, has forms including: single-chamber, upper and lower, left and right, and piano type. The explosion-proof positive pressure cabinet, positive pressure type explosion-proof cabinet has materials including: Q235 high-quality steel plate, stainless steel, available for customers to choose from. B: The applicable range of the stainless steel-proof positive pressure cabinet: 1. It is suitable for flammable and explosive gas or dust environments in chemical, offshore drilling platforms, metallurgy, medicine, light, textiles, food, bioengineering, aerospace engineering, and military industries, as a three-phase four-wire (380V/220V AC low-voltage electrical distribution system for power supply or for monitoring and control of detection instruments, analysis instruments, monitors, touch screens, and large power frequency converters2. It is suitable for dangerous places of zone 1 and zone 2. 3. It is suitable for explosive gas environments of class IIA, I, IIC, with temperature groups of T1-T4. 4. It can be installed indoors or outdoors. C: Technical features of the stainless steel explosion positive pressure cabinet: 1. The product mainly consists of the cabinet body, self-control system, gas distribution system, alarm system, and power distribution system; the body is composed of the positive pressure chamber and the auxiliary chamber, with the positive pressure chamber containing the user's power distribution system components, and the auxiliary chamber containing self-control system. 2. The cabinet-type product uses a GGD cabinet frame, with the main and auxiliary panels in a left-right structure, installed in a trench, with lower incoming lines, front door operation, and rear door maintenance. 3. The box-type product uses a 304 stainless steel welded structure with the main and auxiliary panels in an upper-lower structure, hung for installation, with lower incoming lines, front door operation, and maintenance. 4. The type explosion-proof positive pressure cabinet product.

依客思防爆科技有限公司15392918022

依客思防爆科技有限公司15392918022 扫一扫,手机浏览

扫一扫,手机浏览